__crash_absorber_support_area face setQuesta è una vecchia versione del documento!

Indice

Fem Fundamentals and Chassis Design, spring 2022 course

Lecture Notes

Planar beam structure i.p. and o.o.p. loadings

The beam structure centroidal axis lies on a plane, which is also a symmetry plane for the cross-sections.

Symmetric and skew-symmetric loads with respect to such a plane are called in-plane and out-of-plane loads, respectively.

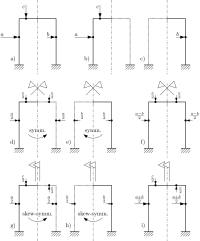

If the superposition of effects holds (e.g., if the structure behaves linearly) each load set only induces an associated subset of the possible components of internal action, see

Symmetric and skew-symm. parts of a general load

A general load is applied to a symmetric structure in a); in b), c) the loads applied on each half structure is treated separately. In d), e) the action on the loaded portion is halved, and symmetrically propagated to the other portion; those symmetric actions are accumulated in the symmetric part of the load f). In g), h) the action on the loaded portion is halved, and skew-symmetrically propagated on the unloaded portion; those skew-symmetric actions are accumulated in the skew-symmetric part of the load i).

Rollbar-like frame

Maxima worksheet v0001, v0002, rollbar_v0002_checkme_insert.wxmxv0003 v0004 v0005 a link rollbar_v0006.wxmx final version 2022

Quarter ladder frame chassis

quarter_ladder_frame_ffcd2022a.wxmx

quarter_ladder_frame_ffcd2022b.wxmx

quarter_ladder_frame_ffcd2022c.wxmx

quarter_ladder_frame_ffcd2022d.wxmx

quarter_ladder_frame_ffcd2022e.wxmx

OTW profile in torsion

profile_in_torsion_v014bis.mud

profile_in_torsion_v016_3d_hole.048.mud

profile_in_torsion_v017b.mud profile_in_torsion_v018b_href.mud profile_in_torsion_v018b_pref.mud profile_in_torsion_v019b_href.mud profile_in_torsion_v019b_pref.mud profile_in_torsion_v020b_href.mud profile_in_torsion_v020b_pref.mud

A Phoney monocoque chassis

RBE3 connector: kinematics, moment distribution; RBE2 vs. RBE3 demonstrator model, screenshot.

Models: v001, v002, v0031), monocoque_chassis_2022_v003b.mud, v004, v005 2), v203, v203motions, …

Properties

Suspension link trusses

Solid circular beam sections, ø12mm, aluminum. Essentially rigid with respect to other chassis structures.

Rear framework

Hollow circular section beam, aluminum.

Main structure: outer diameter ø40mm, wall thickness 1.8mm.

Stiffeners: outer diameter ø30mm, wall thickness 1.2mm.

Composite monocoque

Thicker backbone: 1.8mm aluminum sheet, 25.4mm aluminum honeycomb 3003, density 5.2 lb/ft^3 (hex-3003-td.pdf), 1.8mm aluminum sheet.

Thinner panels: 1.8mm aluminum sheet, 6.75mm same aluminum honeycomb, 1.8mm aluminum sheet.

Frontal shock absorber support plate: provisionally as thinner panels, to be defined based on shock.

Sway (anti-roll) bar

outer diameter ø25mm, wall thickness 2mm, extremely stiff (Super-alloy Z, E=E_steel*1e4, nu=0.3); it may be mechanically isolated at need by deactivating one of the connecting elements to the wheel hub carriers.

Such a “deformable but extremely stiff” linkage modeling should be discouraged in favor of an actual kinematic constraining – i.e. an MPC, since excessive stiffness badly impacts the system matrix condition number (or the integration time step, in the case of explicit dynamic simulations); nonetheless, it allowed for a very straightforward implementation.

Inertial elements modeling

The following spreadsheets are used in defining the equivalent rectangular cuboids for each inertially relevant rigid body: engine, wheel assemblies. The driver inertia is modeled through an 80 kg steel bar spanning roughly from the sternum to the pelvis.

Frontal crash absorber collapse loadcase (inertia relief)

At the element faces belonging to the crash_absorber_bearing_area set (an approx. 155×320 mm area at the front bulkhead), a 25 psi = 0,172 MPa distributed pressure is applied which is due to the honeycomb absorber crushing (see datasheet).

Sparse material

Videos

Interesting stuff

Reference L-shaped cross section, to verify the coupled bending formulas: maxima worksheet, Oxy and G12 oriented MSC.Marc/Mentat linear models. Large rotation, animated hiE lowE models, gif animation.

free_anticlastic_vs_cylindrical_bending.wxmx maxima worksheet for the four point bending test discussion.